#AdditiveManufacturing 3DPrinting Design

Explore tagged Tumblr posts

Text

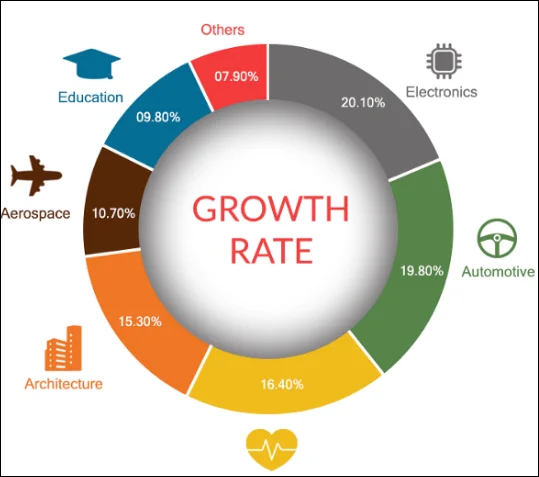

dditive Manufacturing Market size is estimated to reach $96.7 Billion by 2030, growing at a CAGR of 21% during the forecast period 2024-2030. The market for Industrial Remote I/O is primarily driven by the increasing demand for customized products, advancements in technology, reduced lead times and costs, the ability to produce complex geometries, and the use of lightweight and high-strength materials. Additionally, government support and initiatives are promoting the adoption of AM and fostering innovation in the industry.

Plastics material segment accounted for the largest share in the additive manufactruing market size in 2023 and is accounted to grow in the forecast period 2024-2030. This dominance is primarily attributed to the wide range of available plastic materials, their relatively lower cost compared to metal materials, and their suitability for a variety of applications, including prototyping, tooling, and end-use parts. The rise of advanced engineering plastics, such as polyether ether ketone (PEEK) and polycarbonate, has expanded the scope of AM into high-performance applications, including aerospace, automotive, and healthcare.

0 notes

Photo

WASP 3D printer builds eco-friendly homes using local raw earth. The TECLA project showcases this sustainable construction method. The project represents an unprecedented perspective for buildings and new settlements, where the value of local raw materials is amplified by digital design. The double dome solution covers the roles of structure, roof, and external cladding, making the house high-performance in all aspects. How do you think digital design can enhance the use of local materials in construction? In what ways might this integration redefine building practices and performance standards?

#3dprinting#architecture#sustainablebuilding#ecofriendly#wasp#tecla#innovation#construction#greenbuilding#technology#design#futureofconstruction#additivemanufacturing#clayconstruction#architects#3dprint#3dprinter#maker#digitaldesign#pods

1 note

·

View note

Photo

WASP 3D printer builds eco-friendly homes using local raw earth. The TECLA project showcases this sustainable construction method. The project represents an unprecedented perspective for buildings and new settlements, where the value of local raw materials is amplified by digital design. The double dome solution covers the roles of structure, roof, and external cladding, making the house high-performance in all aspects. How do you think digital design can enhance the use of local materials in construction? In what ways might this integration redefine building practices and performance standards?

#3dprinting#architecture#sustainablebuilding#ecofriendly#wasp#tecla#innovation#construction#greenbuilding#technology#design#futureofconstruction#additivemanufacturing#clayconstruction#architects#3dprint#3dprinter#maker#digitaldesign#pods

1 note

·

View note

Text

12 sided shape

Dodecahedron.step

thangs.com/designer/PILED/3d-model/Dodecahedron.step-1106518

Dodecahedrons from 40 to 200mm shown.

I created this Dodecahedron using zoo.dev Text-to-CAD

0.2mm standard 0.4mm hardened steel nozzle Printed on Bambu Lab A1 mini.

#3d printing#additivemanufacturing#3d model#design#3D printing#3Dprint#filament#PLA#3d printer#3d print#3d prints#3D#3DPrint#3DPrinting#Bambu#Bambulab#Bambu Lab#X1C#A1#A1 mini#step#3mf#stl#obj#cad#gcode#additive#3d

1 note

·

View note

Text

#Stereolithography#3DPrinting#AdditiveManufacturing#Architecture#RapidPrototyping#Innovation#Design#SLA#ManufacturingTechnology

0 notes

Text

3D Printing: Explore the world changing technology

In a rapidly evolving technological landscape, one term that has become synonymous with innovation is "3D printing." This transformative technology is reshaping industries and unlocking new possibilities. As we explore the realms of what is 3D printing, we'll unravel its significance and potential.

Understanding the Basics

To comprehend the marvels of 3D printing, let's start with the basics. At its core, 3D printing, or additive manufacturing, builds objects layer by layer from digital models. As the layers stack up, tangible and intricate creations emerge. https://www.youtube.com/watch?app=desktop&v=U-8-lu4mq8o

Applications Across Industries

The impact of 3D printing spans various sectors, from healthcare to aerospace. Medical professionals utilize this technology to craft customized implants, while engineers in aerospace design intricate components with unparalleled precision.

Source: 3ding

Advantages in Prototyping

One of the standout features of 3D printing lies in rapid prototyping. Designers and engineers can quickly bring concepts to life, allowing for faster iteration and refinement.

Environmental Considerations

An eco-friendly aspect of 3D printing is its ability to minimize waste. Traditional manufacturing processes often generate excess material, while 3D printing only uses the necessary amount, reducing environmental impact.

Challenges and Future Prospects

Despite its remarkable benefits, challenges persist, such as material limitations and cost factors. However, ongoing advancements in technology promise to address these hurdles, opening new frontiers for 3D printing.

Conclusion

As we delve into the captivating world of 3D printing, it's evident that this technology is not just a trend but a transformative force. From customized healthcare solutions to streamlined manufacturing processes, the applications are vast, and the potential, boundless. What is 3D printing? It's the gateway to a future where imagination knows no limits. Read the full article

#3Dprinters#3dprinting#additivemanufacturing#Creativity#Design#innovation#Manufacturing#Prototyping#technology

0 notes

Text

#dprintinghealthcare#3dhealthcare#3dprint#3dprinter#3dprinted#design#3dmodeling#3dmodel#ender#3dart#art#3dprints#3ddesign#pla#maker#diy#additivemanufacturing#creality#engineering#filament#impresion#cosplay#technology#dprinters#prusa#thingiverse#ddruck#dprintinglife#print#warhammer

0 notes

Text

🚀 Discover the Future of Additive Manufacturing with RapidShape 3d Printing! 🌟

Experience the cutting-edge world of 3D printing like never before with RapidShape by Imaginarium! 🔬🖨️

🔹 Unleash Creativity: RapidShape empowers you to turn your boldest ideas into reality with precision and speed. Create intricate prototypes, customized products, and stunning designs effortlessly.

🔹 High-Performance 3D Printers: Explore the world of advanced additive manufacturing with RapidShape's state-of-the-art 3D printers. From dental applications to jewelry and industrial parts, their printers cater to diverse industries.

🔹 Expertise You Can Trust: With Imaginarium's expertise in the additive manufacturing field, you can count on top-notch support and guidance throughout your 3D printing journey.

🔹 Accelerate Innovation: Stay ahead of the competition by embracing the innovative solutions offered by RapidShape. Boost your productivity and elevate your product development process.

🔹 Precision & Quality: From micro-detailing to macro-sized projects, RapidShape ensures unmatched precision and exceptional quality in every print.

🔹 Embrace the Future Today: Step into the realm of advanced 3D printing with RapidShape and unleash your creativity like never before.

Visit "https://imaginarium.io/rapidshape/" to explore the possibilities and experience the transformative world of additive manufacturing with RapidShape! 🚀🔧

#Imaginarium#RapidShape#3DPrinting#AdditiveManufacturing#Innovation#PrecisionPrinting#Technology#CreativityUnleashed#ExploreTheFuture#design

0 notes

Text

3D Printing High-Performance Plastics Market to Reach $3.4B by 2033! 🖨️🔧

3D Printing High-Performance Plastic Market is poised for rapid growth, expanding from $1.2 billion in 2023 to $3.4 billion by 2033, reflecting a CAGR of 10.5%. This market is driven by demand for lightweight, durable, and heat-resistant materials across aerospace, automotive, and healthcare sectors.

To Request Sample Report: https://www.globalinsightservices.com/request-sample/?id=GIS21079 &utm_source=SnehaPatil&utm_medium=Article

Key Market Trends

PEEK & PAEK Leading the Market Holding a 38% market share, PEEK (Polyetheretherketone) dominates due to its high strength, heat resistance, and chemical stability, making it indispensable for aerospace and medical applications.

Polycarbonate (PC) Rising Capturing 20% of the market, PC is gaining traction in electronics and consumer goods due to its impact resistance and versatility.

North America & Europe Spearheading Growth North America leads due to technological advancements and strong R&D investments, while Europe follows closely, driven by sustainable manufacturing initiatives. Asia-Pacific is emerging as a high-growth region, fueled by industrialization and government support in China & India.

AI & Automation Reshaping the Industry The integration of AI in design and manufacturing is set to revolutionize 3D printing processes, optimizing material usage and production efficiency.

Market Segmentation

By Material: PEEK, PEI, PPSU, Nylon, PC, ABS, PLA

By Technology: SLA, FDM, SLS, MJF, EBM, DLP

By Application: Aerospace, Automotive, Healthcare, Electronics

By Key Players: Stratasys Ltd., 3D Systems Corporation, Arkema Group

Future Outlook

Despite challenges like high material costs and regulatory constraints, the market’s focus on sustainability, AI integration, and technological advancements presents lucrative growth opportunities. A 15% increase in R&D investments by 2033 underscores commitment to innovation in the sector.

🔹 #3DPrinting #AdditiveManufacturing #HighPerformancePlastics #PEEK #AerospaceTech #AutomotiveInnovation #Medical3DPrinting #PolymerScience #AdvancedMaterials #SmartManufacturing #Industrial3DPrinting #FutureOfManufacturing #SustainableTech #EngineeringExcellence #Thermoplastics #FDMPrinting #3DMaterials #MaterialInnovation #AIinManufacturing #NextGenTechnology #ManufacturingRevolution #PolymerEngineering #LightweightMaterials #R&DInnovation #3DPrintingMarket #TechTrends

0 notes

Text

Recyclable 3D Printing Filament: The Green Future of Printing—Market Growing from $1.2B to $3.8B by 2034

Recyclable 3D printing filament market is projected to grow from $1.2 billion in 2024 to $3.8 billion by 2034, achieving a robust CAGR of 11.6%. This market is centered on eco-friendly filaments crafted from recycled materials, addressing the demand for sustainable manufacturing. These filaments, including PLA and PETG, are derived from post-consumer and post-industrial waste, enabling reduced environmental impact while supporting industries like prototyping, consumer goods, and education.

To Request Sample Report: https://www.globalinsightservices.com/request-sample/?id=GIS11069 &utm_source=SnehaPatil&utm_medium=Article

The growth of this market is fueled by increasing environmental awareness and advancements in 3D printing technologies. PLA (Polylactic Acid) leads the segment, thanks to its biodegradability and user-friendly nature, appealing to both professionals and hobbyists. PETG (Polyethylene Terephthalate Glycol) follows closely due to its strength, durability, and recyclability.

Regionally, North America dominates the market, driven by its innovative ecosystem and adoption of sustainable practices. Europe is a strong contender, with nations like Germany and the Netherlands emphasizing circular economy initiatives. Meanwhile, the Asia-Pacific region is witnessing rapid growth, led by industrialization and investments in sustainable technologies in countries such as China and Japan.

In 2023, the market volume reached 250 million metric tons and is forecasted to double by 2033. The PLA segment held a commanding 45% share, followed by PETG at 30% and ABS at 25%. Companies like Filamentive, 3D Printlife, and ColorFabb are at the forefront, driving innovation and enhancing the recyclability of filament products.

Although challenges such as high production costs and limited consumer awareness persist, the market holds immense promise. Stringent EU regulations on plastic waste management and increasing R&D investments are paving the way for advancements. With AI-driven design optimization and sustainable manufacturing practices, the future of recyclable 3D printing filaments looks brighter than ever.

#3DPrinting #SustainableManufacturing #RecyclableFilament #EcoFriendlySolutions #PLA3DPrinting #PETGMaterials #CircularEconomy #AdditiveManufacturing #GreenTechnology #3DPrintingInnovation #PrototypingSolutions #BiodegradableMaterials #3DPrintingSustainability #EcoInnovation #RecycledFilaments #Industrial3DPrinting #FutureOf3DPrinting #SustainabilityGoals #3DPrintingForGood #PlasticWasteReduction #AdvancedMaterials #TechForSustainability #RethinkPlastics #AIIn3DPrinting #GreenManufacturing

0 notes

Link

Link3D introduced its True Shape Nesting at Rapid + TCT in additive manufacturing.

0 notes

Photo

@aaronpdesign founder of @fequalsf to show some computational workflows at the Computational Design: NEXT 7.0 conference. (@cdnext). - Join now, link in bio or: http://parametric-architecture.com/cd-next/ - Aaron is an Industrial Designer, Computational Designer, Digital Fabricator and the Founder of f=f. . . . @cdnext @parametric.architecture @designmorphine @ekimroyrp @pa.next @hamithz @thepaacademy #arch #3dprinting #footweardesigner #footweardesign #footwear #additivemanufacturing #3dmodeling #artist #parametric #parametricdesign #parametricarchitecture #computationaldesign #computational #computation #grasshopper3d #rhino3d #rhinoceros3d #generativedesign #algorithm #design #art #architecture #conference #superarchitects #next_top_architects #architecture_hunter #architecturestudent #cdnext (at 𝓣𝓱𝒆 𝓤𝒏𝒊𝓿𝒆𝒓𝒔𝒆) https://www.instagram.com/p/CW09BD7P2Gv/?utm_medium=tumblr

#arch#3dprinting#footweardesigner#footweardesign#footwear#additivemanufacturing#3dmodeling#artist#parametric#parametricdesign#parametricarchitecture#computationaldesign#computational#computation#grasshopper3d#rhino3d#rhinoceros3d#generativedesign#algorithm#design#art#architecture#conference#superarchitects#next_top_architects#architecture_hunter#architecturestudent#cdnext

3 notes

·

View notes

Photo

WASP 3D printer builds eco-friendly homes using local raw earth. The TECLA project showcases this sustainable construction method. The project represents an unprecedented perspective for buildings and new settlements, where the value of local raw materials is amplified by digital design. The double dome solution covers the roles of structure, roof, and external cladding, making the house high-performance in all aspects. How do you think digital design can enhance the use of local materials in construction? In what ways might this integration redefine building practices and performance standards?

#3dprinting#architecture#sustainablebuilding#ecofriendly#wasp#tecla#innovation#construction#greenbuilding#technology#design#futureofconstruction#additivemanufacturing#clayconstruction#architects#3dprint#3dprinter#maker#digitaldesign#pods

0 notes

Photo

WASP 3D printer builds eco-friendly homes using local raw earth. The TECLA project showcases this sustainable construction method. The project represents an unprecedented perspective for buildings and new settlements, where the value of local raw materials is amplified by digital design. The double dome solution covers the roles of structure, roof, and external cladding, making the house high-performance in all aspects. How do you think digital design can enhance the use of local materials in construction? In what ways might this integration redefine building practices and performance standards?

#3dprinting#architecture#sustainablebuilding#ecofriendly#wasp#tecla#innovation#construction#greenbuilding#technology#design#futureofconstruction#additivemanufacturing#clayconstruction#architects#3dprint#3dprinter#maker#digitaldesign#pods

0 notes

Photo

A wonderful 3D Printed Urban Cabin by @dusarchitects . The 3D Printed Urban Cabin rethinks intimacy and individual space within the city. A precise insertion changed the former industrial area from a vast empty non-place into a retreat to escape the speed of everyday life and to enjoy summer, the waterfront and the sunset with friends or by your self. Photos by: Ossip #architecture #residential #technology #3dprinting #3dprints #3dprinters #3dprinted #3dprinter #3dprint #3dprintedarchitecture #roboticmanufacturing #architecture #architect #design #mimar #mimarlık #sustainability #additivemanufacture #parametric #interiordesign #parametricarchitecture #construction #maker #civilengineering #parametricdesign #computation #house #housedesign #sustainability #3dprintedcabin @designstudio_mag Digital Architecture and Design magazine (presso New York, New York) https://www.instagram.com/p/CPftJs0rMuq/?utm_medium=tumblr

#architecture#residential#technology#3dprinting#3dprints#3dprinters#3dprinted#3dprinter#3dprint#3dprintedarchitecture#roboticmanufacturing#architect#design#mimar#mimarlık#sustainability#additivemanufacture#parametric#interiordesign#parametricarchitecture#construction#maker#civilengineering#parametricdesign#computation#house#housedesign#3dprintedcabin

5 notes

·

View notes

Video

A Nautilus Gear from thingiverse 🥰 why the hell do you need a fidget spinner when you can 3D print one of these! . . . . . #3ddesign #3dprint #3dprinted #3dprintedmodels #3dprinter #3dprinters #3dprinting #3dprintinglife #3dprints #additivemanufacturing #architect #architecture #art #creality #design #digitalart #electricalengineering #engineer #engineering #engineeringlife #engineers #filament #instagood #intrestingfacts #love #maker #mechanicalengineering #pla #rendering #thingiverse (at Johannesburg) https://www.instagram.com/p/CTL4jMWDyG0/?utm_medium=tumblr

#3ddesign#3dprint#3dprinted#3dprintedmodels#3dprinter#3dprinters#3dprinting#3dprintinglife#3dprints#additivemanufacturing#architect#architecture#art#creality#design#digitalart#electricalengineering#engineer#engineering#engineeringlife#engineers#filament#instagood#intrestingfacts#love#maker#mechanicalengineering#pla#rendering#thingiverse

1 note

·

View note